Continuous improvement and innovation, providing customers with better molds, allowing customers to earn more profits. Customers will trust “Liusenmould”, Liusen Mold can survive and develop, and realize the “win-win model”.

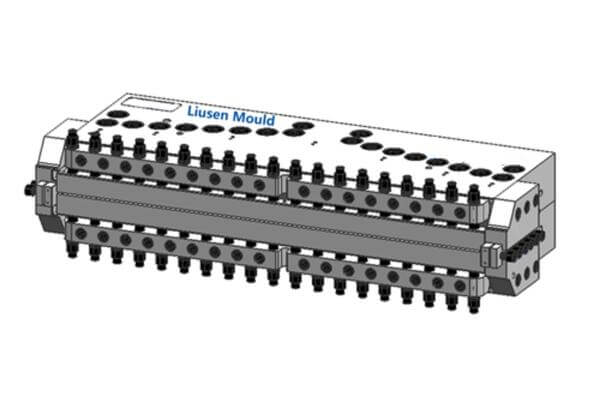

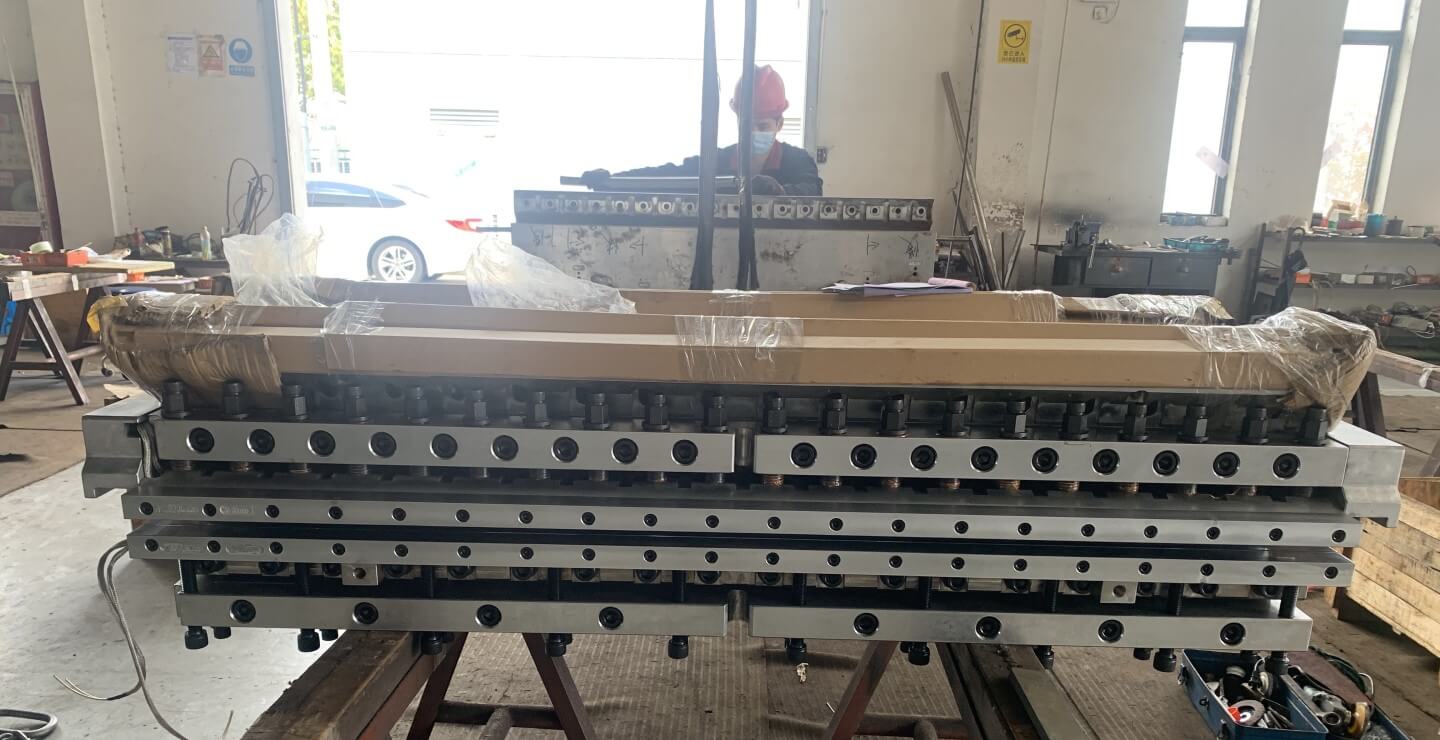

The upper and lower parts are integrated; the non-choke bar design can remove the mechanical marks on board surface. This new design of non-choke bar T-die effectively promotes the toughness, rigidity, weather ability and gloss of roofing tile. It can lower down the production formula cost and improve product quality. And the reasonable flow channel can extend the running time.

Die width:1280-1300mm;Adapator A/B/A; Adapator A/B/C/B

Die material:P20

Product width:1050mm

Product thickness:2-5mm

No choke bar inside the T-die; no movable die lip; integral upperdie body; die lip elastic micro adjustment.

Evenly thickness of finished product, smooth surface, withoutmechanical lines on product surface, easy in operation andcleaning, high adaptation to screw and formula, high output, lowwaste and cost.

Different size of PVC roofing tile T-die can be tailor-madeaccording to customer’s requirements.

Q1: What material of extrusion product, PVC, PP, PS, ABS, PC or PET?

Q2: Could you please provide me diamensional drawing, structure drawing and photos of your product?

Q3: How many meters per gram is the weight of your required product? (?m/g)

Q4: What is the extrusion speed? (?m/min)

Q5: What is the model of your extrusion machine?

We can produce if you can answer the following question.

Just leave your question & you are done. You will get back in shortest possible time. We will provide you with free plans and quotations.

Yixing City Formwork Science and Technology Industrial Park.

No. 58, Moyu South Road, Anting Town, Jiading District.

Powered by LinsenMould. All rights reserved.

We will contact you within 1 working day, please pay attention to the email with the suffix “@liusenmould”.