Continuous improvement and innovation, providing customers with better molds, allowing customers to earn more profits. Customers will trust “Liusenmould”, Liusen Mold can survive and develop, and realize the “win-win model”.

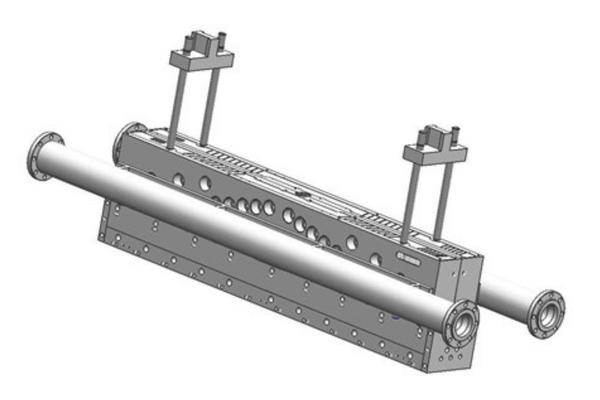

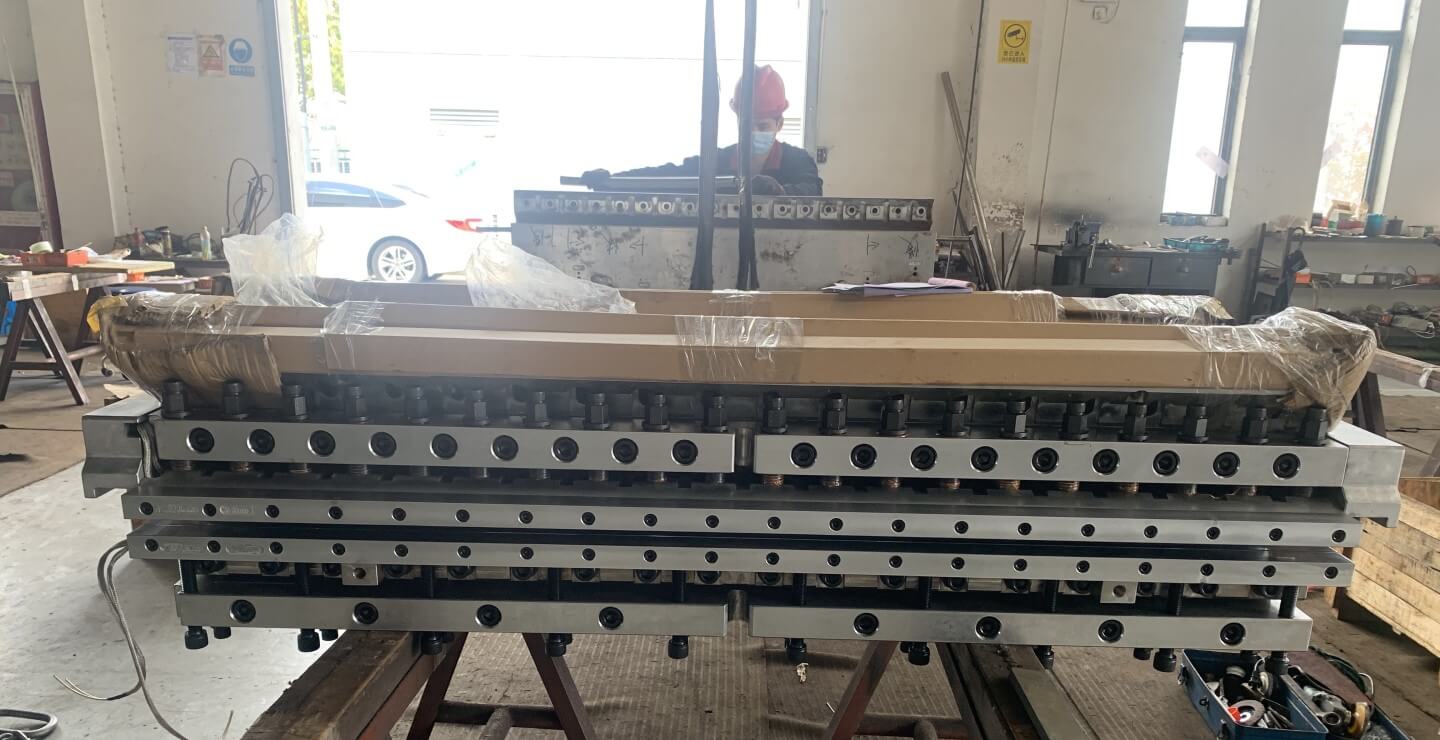

The meltblown nonwoven process is using high-speed hot air to draw the melt stream from spinneret hole of die. After this process, microfiber will be formed and gathered on the collecting screen or roller. At last the meltblown nonwoven fabric is formed by the self-bonding microfiber. The die acts a very important role in this process, especially for fabric’s thickness uniformity. So it requires high-precision manufacturing for die.

Effective width of nozzle: 400mm, product width: 400mm, suitable for cutting into 2 pieces of 175mm finished meltblown fabric to make 2 pieces of 3 ply mask.

Effective width of nozzle: 580mm, product width: 580mm, suitable for cutting into 3 pieces of 175mm finished meltblown fabric to make 3 pieces of 3 ply mask; Or cutting into 2 pieces of 260mm finished meltblown fabric to make 2 pieces of KN95(KN90) mask.

Effective width of nozzle: 750mm, product width: 750mm, suitable for cutting into 4 pieces of 175mm finished meltblown fabric to make 4 pieces of 3 ply mask.

Effective width of nozzle: 1100mm, product width: 1100mm, suitable for cutting into 6 pieces of 175mm finished meltblown fabric to make 6 pieces of 3 ply mask; Or cut into 4 pieces of 260mm finished meltblown fabric to make 4 pieces of KN95(KN90) mask.

Effective width of nozzle: 1610mm, product width: 1610mm, suitable for cutting into 9 pieces of 175mm finished meltblown fabric to make 9 pieces of 3 ply mask; Or cut into 6 pieces of 260mm finished meltblown fabric to make 6 pieces of KN95(KN90) mask.

Q1: What material of extrusion product, PVC, PP, PS, ABS, PC or PET?

Q2: Could you please provide me diamensional drawing, structure drawing and photos of your product?

Q3: How many meters per gram is the weight of your required product? (?m/g)

Q4: What is the extrusion speed? (?m/min)

Q5: What is the model of your extrusion machine?

We can produce if you can answer the following question.

Just leave your question & you are done. You will get back in shortest possible time. We will provide you with free plans and quotations.

Yixing City Formwork Science and Technology Industrial Park.

No. 58, Moyu South Road, Anting Town, Jiading District.

Powered by LinsenMould. All rights reserved.

We will contact you within 1 working day, please pay attention to the email with the suffix “@liusenmould”.